Boring

Boring is an operation to enlarge and finish a hole accurately. The work is held in contact with a single point on a lathe or milling machine.

Broaching

Broaching is a one stroke cut performed with a toothed tool on either an internal or external surface.

Drilling

Drilling creates semi-precision round holes or recesses. More precise boring, reaming or tapping often follows. The machine that holds the bit is a drill press. Drill presses may be upright or radial. “Sensitive” drill presses create small holes at high speed. Other types include gun drilling machines for deep holes (such as those in guns) using a variety of spindles, and gang drilling machines that consist of a bed of different drill heads to perform numerous drill operations in rapid sequence. Usually the bit revolves while the material is stationary but the reverse is also possible.

Grinding

Grinding uses an abrasive rotating wheel to either cut or grind to a fine finish. Different types of grinder can reach internal or recessed surfaces. Non-precision bench grinders are used when accuracy is less critical, but precision grinding produces smooth high tolerance finishes. A succession of finely graded wheels may be used.

Honing

Honing is the use of an abrasive rotating tool on internal surfaces to create extremely smooth holes. (Lapping is similar but uses a rotating brush).

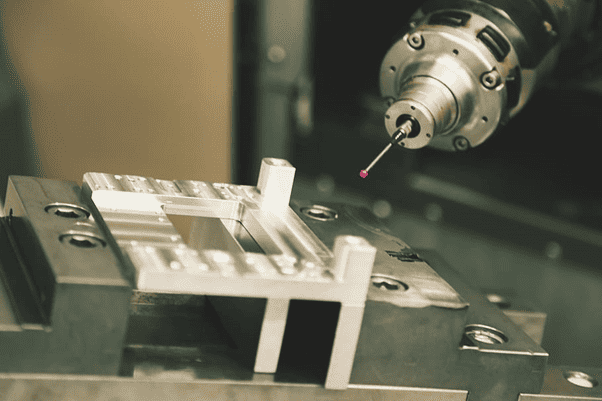

Milling

Milling machines create flat surfaces using a rotating tool. They consist mainly of a flat bed and a horizontal or vertically mounted spindle. Horizontal mills are used for heavy stock removal while vertical mills are lighter duty but highly flexible.

Reaming

Reaming removes small amounts of material from an already drilled hole.

Shaping

When the worked item is fed toward a reciprocating cutting tool that removes material on each stroke, it is called shaping. Different types of shaping tool are used to produce

vertical, horizontal, or angular surfaces (including slotters and key seaters).

Tapping and threading

When threads are cut on the outside of a component (such as a bolt) it is called threading. When they are cut internally (such as a nut) it is called tapping. Tapping machines are often electric or pneumatic (see https://www.cotswold-machinery-sales.co.uk/roscamat/).

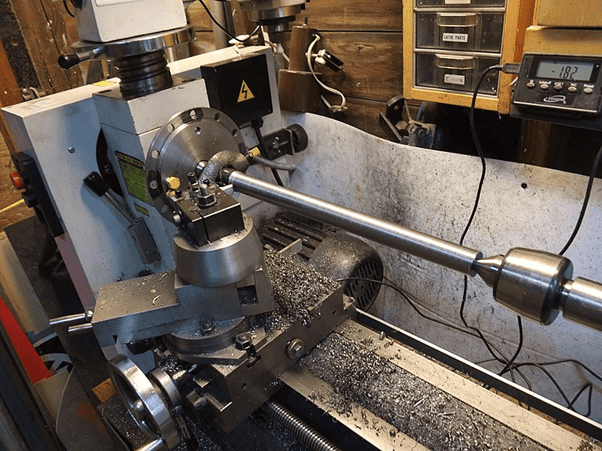

Turning and facing

When a lathe removes material from the outside diameter of a turned piece it is called turning. When the material is removed from the end of the piece it is called facing.